The Annex 1 of the EU GMP Guide “Manufacture of Sterile Medicinal Products” is considered the most important European regulatory standard for the manufacture of sterile pharmaceutical products.

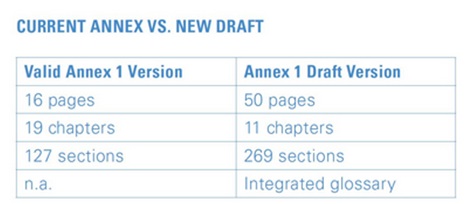

It is undergoing a complete overhaul in collaboration with the EMA, WHO and the PIC / S*. One of the most extensive revisions since its implementation in the 1970s. A draft of the ‘new Annex 1’, published in December 2017, made it clear that the guideline will not only be updated with some parts completely rewritten, but also more detailed, stricter and with additional content.

Reasons for the revision

Since the last revision of Annex 1 in 2007, many manufacturing and testing innovations have entered the market. New technologies such as closed disposable systems have evolved and quality risk management principles have been introduced, notably the ICH Q9 and I Q10.

Challenges for the industry

Comparing the currently valid with the draft guideline, it is revealed where the focus will lie of the revised version: Experts see changes especially in the areas of quality risk management, contamination control strategies and environmental and process monitoring:

- Introduction of the principles for quality risk management is a logical step, as it has already been anchored in other regulations in recent years. It is referred to in many chapters of the guideline. An appropriate understanding of the processes is important for effective quality risk management.

- Another focus is the prevention of cross contamination and ensuring the sterility of manufactured products. Therefore, technical solutions for minimizing the risk of contamination, such as RABS, isolators or aseptic compounds, are emerging in the new draft version of Annex 1. In general, the topic Contamination Control Strategy plays an important role in the draft.

- The environment and process monitoring is dedicated to a separate chapter. A topic that contains further aspects for manufacturing processes. These include e.g. a new definition of hygiene areas or the adaptation of Class A limits.

The revision of Annex 1 will therefore result in extensive changes in the GMP environment. Therefore, pharmaceutical and biotech companies have already started to address the new requirements in the manufacture of their aseptically pharmaceutical products.

Vetter is ready for Annex 1

As one of the world’s leading pharmaceutical service providers for sterile injection systems, Vetter is also affected. Therefore, the company has already actively participated in the opportunity of commenting on the draft revision of the Annex 1. Furthermore, with an internal GAP the upcoming changes have been addressed. The result: The company is well-positioned and has a good basis in the currently most addressed topics within the draft paper. In particular, the use of Vetter owndeveloped Cleanroom Technology (V-CTR®) offers many advantages concerning avoiding contamination and ensuring the sterility of the manufactured products.

*EMA: European Medicines Agency, WHO: World Health Organization, PIC/S: Pharmaceutical Inspection Co-operation Scheme