By Jochen Ulrich Scheil , Managing Director, Uhlmann Packaging Systems (Shanghai) Co Ltd

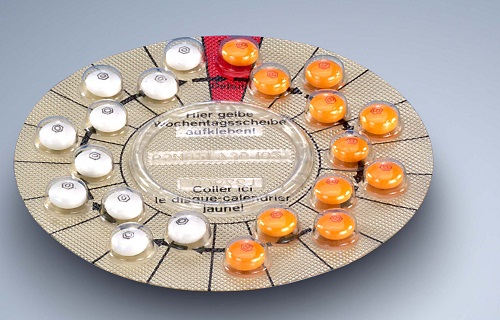

With its sheer size of 1.364 Billion population the China Pharmaceutical market offers huge opportunities as more and more people gain access to medicine, not only Traditional Chinese Medicine (TCM), but also more and more Western medicine, which is produced in huge volumes. That’s why China has become the most important as well as the biggest market for the use of high speed blister packaging machines.

After several years of annual GDP growth rates beyond 10% the Chinese economy has now slowed down and will be transformed from a mainly manufacturing focused industry into a more service / consumption based industry with a GDP growth rate estimated with 7% for 2015 – the lowest in two decades, but a figure other Western countries only can dream of.

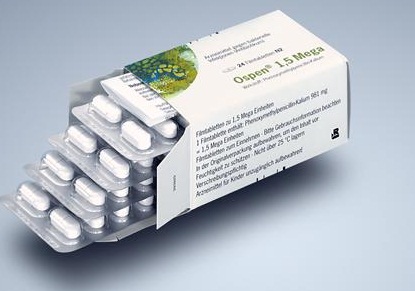

Chinese Pharmaceutical companies are taking a more careful approach in investing; as such modest growth is also influencing the financial markets hence companies will think twice before investing also caused by a less favorable exchange rate when buying equipment from European manufacturers. On the other hand there is a strong need for a lot of Pharmaceutical companies – both multinational and local – to upgrade their blister packaging equipment and to replace it with more efficient and reliable equipment in order to meet the strict cGMP guidelines set by the local authorities.

Chinese Pharmaceutical companies are taking a more careful approach in investing; as such modest growth is also influencing the financial markets hence companies will think twice before investing also caused by a less favorable exchange rate when buying equipment from European manufacturers. On the other hand there is a strong need for a lot of Pharmaceutical companies – both multinational and local – to upgrade their blister packaging equipment and to replace it with more efficient and reliable equipment in order to meet the strict cGMP guidelines set by the local authorities.

But this modest and hopefully sustainable growth also brings opportunities for all European blister machine manufacturers as pharmaceutical companies need to become more flexible and need to produce smaller batches instead of high volumes of one product only. There are very suitable solutions – so called Blister Express Center’s – available from the world’s market leader of blister packaging machinery, who have been the right answers to this changing demand for medium batch sizes.

But still the demand for higher speed / large batch sizes and flexible blister packaging machines persists. A trend that will continue in the Chinese Pharma market as the population is getting older hence there is a need to take medicine for a longer period of time.

A growing number of large local Pharmaceutical companies understood this need already many years ago and begun to replace their old blister packaging equipment or to upgrade it to the latest technology available, all with the aim to extend the life span of the equipment. Currently there are Pharmaceutical companies in China using blister packaging equipment from the world’s market leader for more than 25 years and they do not plan to retire such reliable equipment.

The majority of the pharmaceutical packaging equipment used in China is designed to pack products in blister. In USA such products are mostly packed in bottles using e.g. so called Integrated Bottle Center’s (IBC) which offer a compact alternative to blister packaging lines.

The majority of the pharmaceutical packaging equipment used in China is designed to pack products in blister. In USA such products are mostly packed in bottles using e.g. so called Integrated Bottle Center’s (IBC) which offer a compact alternative to blister packaging lines.

Another trend which can be foreseen is the demand for efficient and highly automated equipment. A requirement, which only few of the leading blister packaging machinery manufactures are able to fulfill. Rising labor costs in the big cities such as Shanghai, Beijing, Tianjin, Guangzhou, etc. force the pharma companies to rethink about the way they manufacture, not only to be more competitive, but to me more productive making more out of their existing equipment. Quality of the packaging material, machine availability and efficiency as well as operating procedures have a big influence in the overall equipment efficiency. Some European manufacturers even offer a detailed production analysis for their customers in order to find out where to improve.

Shortage of skilled labor is becoming a major issue for all pharmaceutical companies, as they can retain their staff only through intensive training and constant education offered by the manufacturer of such packaging equipment. Smart Operating systems/panels which are easy to use (like your smart phone) will help the staff to run the equipment more efficiently and also guide them with possible solutions in case there is a problem. Such kind of smart solutions gain popularity among machine manufacturers as they are offered also in local languages which makes it easier for the less skilled staff to operate easily.

Shortage of skilled labor is becoming a major issue for all pharmaceutical companies, as they can retain their staff only through intensive training and constant education offered by the manufacturer of such packaging equipment. Smart Operating systems/panels which are easy to use (like your smart phone) will help the staff to run the equipment more efficiently and also guide them with possible solutions in case there is a problem. Such kind of smart solutions gain popularity among machine manufacturers as they are offered also in local languages which makes it easier for the less skilled staff to operate easily.

Due to requirements of the Food & Drug Administration in China it is mandatory to apply a 2D-Barcode on each carton so that the product can be tracked and traced throughout the manufacturing process, logistics chain until it has reached the final point of sale, the pharmacy. Such technical requirements can only be met by intelligent Track & Trace Systems integrated into the blister packaging equipment which work on machine level, but also can be linked to the production site and even to a global system commonly used by multinational pharmaceutical companies. A lot of efforts are made in order to reduce counterfeits so that the patient can be sure to take an Original product.

The Chinese Pharmaceutical market remains very dynamic and challenging, but those companies offering the right pharmaceutical packaging equipment and having a hardworking, dedicated service team established locally based on the principle “in China and for China” will be able to benefit from the opportunities offered in one of the world’s biggest Pharma markets.

Personal data Jochen Ulrich Scheil

Managing Director

Uhlmann Packaging Systems (Shanghai) Co., Ltd.

Company Description

Uhlmann, founded in 1948, is a leading supplier and trendsetter for pharmaceutical packaging machinery as well as solutions to optimize the pharmaceutical packaging process. Thanks to a range of products that has helped shape the industry, many reputable pharmaceutical companies are Uhlmann customers. Multum non multa; quality not quantity: the company’s success confirms that Uhlmann’s strategy to concentrate solely on the pharmaceutical industry is correct. We offer best support through our qualified and experienced staff.

Our Vision: Strong, Open-minded, Reliable