Quality by Design (QbD) is a concept that has become mainstream in the pharmaceutical manufacturing space in recent years.

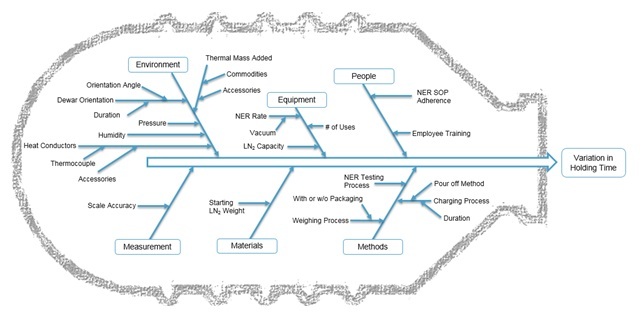

QbD is a science- and risk-based approach to quality that identities, measures and defines the critical processes that impact quality and provides a pathway to introduce quality and risk management into the design process. The process begins with a target product profile (TPP) that describes the intended use, safety and efficacy parameters of the product. Critical quality attributes (CQAs) such as equipment hold time, nitrogen evaporation rate (for dry vapor liquid nitrogen shippers) and orientation will need to be identified based on the TPP. By understanding the design space (the sum total of all variability) and control space (the sum total of all acceptable variability),CQAs can then be utilized to produce a process supporting the TPP to provide enhanced process controls. The QbD concept within logistics cannot be implemented without an in-depth understanding of the equipment and processes by which critical pharmaceutical commodities are packaged and shipped. QbD incorporates modern tools such as GPS-enabled, real-time condition monitoring systems to preemptively understand and ultimately work to control variation. The process cannot be implemented without the ability to dynamically measure and understand the variation that exists in the logistics process by using historical data, testing and modeling to help analyze, forecast and eliminate risk during transport.

The QbD concept within logistics cannot be implemented without an in-depth understanding of the equipment and processes by which critical pharmaceutical commodities are packaged and shipped. QbD incorporates modern tools such as GPS-enabled, real-time condition monitoring systems to preemptively understand and ultimately work to control variation. The process cannot be implemented without the ability to dynamically measure and understand the variation that exists in the logistics process by using historical data, testing and modeling to help analyze, forecast and eliminate risk during transport.

Within regenerative therapy product distribution, for example,one needs to have the aptitude and systems to measure and understand not only the validated hold time of a cryogenic dry vapor liquid nitrogen shipper, but also to understand the influence on hold time due to repeated use, charging, LN2 capacity, orientation and shock, as well as a myriad of other external events. Additionally,this data must be used to manage the dynamic risk to the product. The ability to effectively measure these factors requires intensive data collection of every dry vapor shipper in use during every transit event, providing the ability to track historical shipper performance at the unit level.

The key to QbD implementation is the ability to measure and preemptively control variation in real time using modern tools such as GPS-, cellular- and Wi-Fi enabled condition monitoring systems. Sophisticated condition monitoring systems can provide the ability to measure and understand the in-transit variation that exists, as well as to collect critical data to help forecast,analyze and design process controls to eliminate the deleterious effects of the observed variation, using three basic activities:

- Evaluating the actual performance of the equipment and in-transit processes

- Comparing the actual performance of the equipment and in-transit processes with goals

- Acting on any discrepancies observed during the in-transit process

If we are to look at an example of this process in action, one intransit variable critical to the transportation of regenerative therapies is the orientation of the dry vapor liquid nitrogen shipper during transit. It is well documented that a dry vapor liquid nitrogen shipper’s orientation heavily impacts the overall hold time of the shipper. A dry vapor liquid nitrogen shipper on its side or turned upside down can take hours or even days off its prescribed hold time, in some cases reducing its hold time by as much as 70 percent.

In studies Cryoport conducted using its TM SmartPak II condition monitoring systems, we could observe intransit misorientation during a transportation study in 32 of 33 shippers (we looked at both dry vapor liquid nitrogen shippers as well as dry ice packaging) with an average time misoriented between 10 and 30 percent depending on the package type. In fact, there were multiple examples of cryo-shippers that spent more than 75 percent of their in-transit time misoriented.

The conclusion reached was that QbD was a critical necessity for the effective cryogenic transportation of regenerative therapy materials.Using static validation studies alone was insufficient in managing risk, as the most thoroughly qualified dry vapor liquid nitrogen shipper could lose 70 percent of ts validated hold time due to in-transit handling. Using data captured dynamically by means of real-time GPS, cellular and Wi-Fi condition monitoring systems, one can develop algorithms that can dynamically adjust and predict the hold time of a dry vapor liquid nitrogen shipper while it is en route and more effectively manage the risk to the commodity.This enables the user to understand the in-field remaining hold time of a dry vapor liquid nitrogen shipper in hours, not days, and develop risk mitigation and intervention procedures to prevent product loss before it occurs.

Automating the risk management process through effective use of QbD using real-time informatics is a critical consideration when contemplating support of a commercial product in the field of regenerative medicine. Informatics to capture, interpret and predict, as well as to provide automated alerts and pre-defined escalation protocols based on the nature of the data captured for hundreds if not thousands of concurrent shipments will be critical in the effective launch of these therapies. QbD processes provide the foundation enabling such an approach to be effective.

The QbD process can be extrapolated beyond the cryogenic transportation space. If we are to look at temperature ranges such as 2-8°C, one can envision augmenting a summer/winter validation protocol with dynamic remaining hold time calculations that account for factors such as external temperature,humidity and atmospheric pressure to create algorithms that have the capability to track remaining hold time of vacuum paneled shippers to a matter of a few hours and significantly minimize or even eliminate temperature excursions as acceptable risk factors in the process.

This acceptable variance in temperature range is much tighter in the 2-8°C space than the cryogenic space (only 6 degrees versus the large range, -150°C and below). Therefore, the ability to monitor and control temperature excursions is just as or perhaps even more critical.