The growing demand for increased tablet quantities and the goal of reducing time to market is putting pressure on manufacturers to produce quality tablets in record time. This calls for the implementation of efficient procedures, quality equipment and an understanding of the manufacturing process. One key area to examine is the availability and condition of tooling as this is of primary importance for uninterrupted production.

Ensuring tablet punches and dies are kept in optimum condition to produce high quality tablets is critical for efficient productivity. Tablet tooling is hugely influential on successful mass-production, however many manufacturers view tooling as an expendable item which can be easily replaced. Rather than maintaining existing tooling, which is considered an unnecessary and time consuming process, new tooling is used. This approach however can affect manufacture by adding time to production and expense that is not necessary.

Keeping Tooling in Check

Keeping tooling in good working condition not only reduces tablet press downtime, but also minimises compression problems. 85% of punch and die problems can be traced back to poor handling and aftercare procedures. This highlights just how important it is to implement maintenance procedures into everyday production.

There are many problems which are a result of badly maintained tooling but the most significant is sticking.Sticking is the most common problem experienced during production and can severely affect output and increase costs if not resolved quickly and effectively.

Sticking is the accumulation of granule on the punch tip face. There are several different reasons why sticking occurs and it can include everything from the physicochemical properties of the formulation, to the surface characteristics of the punch face. The condition of the tooling is another factor that is hugely influential in controlling the problem of sticking.

If punches and dies are worn through the continuous compaction of granules, and non-stick coatings and treatments are not maintained, sticking is inevitable.Unless maintenance procedures are put in place where wear can be monitored and identified through early diagnosis and assessment measures, the negative effect on tablet output will increase and issue like sticking will continue to be a problem.

Making Steps to Better Production

By employing good handling, operating, care and maintenance practices with both the tooling and the tablet press, common problems can be prevented. It is important to employan established maintenance process that makes certain tablet tooling is kept in a workable condition. A simple way to ensure this is achieved is to follow a seven step method which addresses good tool care, maintenance, storage and handling procedures.

The seven steps include clean, assess, repair, measure, polish, lubricate and store. These are designed to provide a consistent approach to tooling maintenance and aids production at all times. The steps should become a Standard Operating Procedure within tablet production and used consistently to ensure punches and dies are clean, un-damaged, within specification and ready for use at all times.

Step one: Clean. Cleaning is the most critical step (along with Step 5: Polish) to undertake in the process. The clean identifies multiple and clear benefits during production, as well as reducing tablet press downtime and helping to increase productivity. During this step any damage to the punch tip edges in the form of nicks and bruises will be highlighted. The procedure also removes problematic residue that if left untreated may cause production issues like sticking. It is only once the clean has been executed that all other steps may be followed.

Step two: Assess.Following a comprehensive clean, punches and dies should then be inspected to check the condition and its suitability to produce tablets of sufficient quality. This should be performed thoroughly and on a regular basis to detect obvious damage like wear or corrosion and to establish if the cleaning step was completed successfully. Identifying damage off the tablet press is more efficient than running tablet production with faulty tooling.

Step three: Repair. Un coated tooling that has experienced light surface wear, corrosion, and minor damage, can be repaired back to a use able condition. This can be achieved through the use of a motorised chuck with double ended polishing motors and abrasive polishing accessories. However, it is vital that the repair is accurately and extensively completed by an experienced technician to ensure tooling does not exceed tolerance limits. The process should also be avoided on treated tooling as it can remove the coating from the punch, leading to reduced quality and exasperating problems like sticking.

Step four: Measure. Critical tooling dimensions must be maintained within an acceptable working tolerance range for good tablet weight, thickness control and dosage consistency. This will ensure accuracy and quality throughout the manufacturing process. Once cleaning and polishing has taken place, measurement can be completed with simple hand-held micrometres, vernier callipers, and height gauges, to more advanced devices like semi-automatic, computerised digital gauging systems.

This step also ensures that relevant measurement data has not been influenced by extraneous variables, such as oil or compacted granule, and therefore presents an accurate observation and analysis of the process equipment. Measuring should be carried out consistently at regular intervals to check for signs of natural wear during compaction.

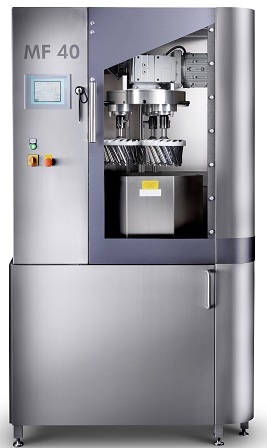

Step five:Polish. Automated polishing helps to keep tooling in optimum condition, and ensures punches are evenly polished to a consistent finish. By following this step, costly tablet press downtime caused through poorly maintained tool surfaces will be reduced.

Controlled, light polishing on a frequent basis will ensure the tools are maintained to a smooth finish, helping to maximise tooling life.

Step six:Lubricate. Lubrication is necessary as it serves to protect, preserve and support continuous press tooling operations. For lubrication purposes, a non-toxic, FDA-compliant oil or grease should be used. In addition, consider using oils and greases that include several properties to help the manufacturing process, including:

- Machine component protection

- Lubrication performance

- A wide temperature range

Step seven: Store. Tooling storage and transportation should be specifically designed and developed with high security and safety handling considerations a priority as this reduces the probability of damage and deterioration. Custom-built storage cabinets and storage containers are just one solution that provides this protection.

The tooling itself must be separated to ensure it avoid contacts with other punches and so that the tooling condition does not deteriorate during storage. Due to the nature and weight of tablet tooling, it should only be handled with care and attention and only when necessary.

Keeping Track through Technology

When there are several production lines and tablet presses running simultaneously keeping track of maintenance procedures can be understandably difficult. The availability and condition of tools is of primary importance for uninterrupted production so it is important that data is kept up to date.

Through the use of a tool management system, tablet manufacturers can fulfil a core requirement of managing tooling in an ordered and traceable way. This advanced technology keeps track of where every tool is located, what condition it is in, how long it has been in service. It also identifies maintenance issues or poor handling problems by auditing all tooling and its respective processes.Without this information either unnecessary tooling replacements are made, reducing productivity, or punches are used when they should be in maintenance or replaced.

This then leads to problems with the end tablet when it is found that the tooling being used does not meet the highly demanding process of tablet manufacture. Rejected tablets, wasted formulation and press downtime is the typical result.

Smooth Operator

Solid dose manufacturers are under pressure to make production more cost-effective. It needs to be quicker, more effective and able to keep in-line with competition from developing markets. For these reasons, it is important to have the right ‘tools’ for the job. The importance of an effective tool maintenance process cannot be overlooked because it plays such an important role in the effectiveness of mass production. One of the most influential procedures to affect production is tool maintenance.

The main purpose of regular maintenance is to ensure that the tablet tooling required for production is operating at 100% efficiency at all times. Through the seven step process, minor problems can be detected and corrected before becoming a major problem that can shut down a production line. When combined with a tool management system,manufacturers will make processes more effective and proficient, therefore facilitating increased output, efficiency and product quality.

About Author

Alex Bunting: Marketing Manager at I Holland Limited