Trending Now

Breaking news:

News

Ensuring optimal product integrity with pharmaceutical preservation strategies

Preserving the potency of pharmaceutical products is paramount in the healthcare industry. Maintaining temperature stability is crucial for safeguarding vaccine efficacy from production to administration....

BioPharma

Automated Fluid Transfer in Biomanufacturing Systems

Automation in Fluid Transfer: From Manual to Modular Systems in Biomanufacturing

A fundamental component of biomanufacturing, fluid transfer links upstream and downstream processes and enables...

Popular:

Featured

Smart Drug Delivery Systems Redefine Healthcare Innovation

Smart Drug Delivery Systems: Emerging Market Trends

Driven by technical...

White Papers

Transform documentation into a competitive advantage

In our latest white paper, learn:

How AI unlocks...

Articles

Interviews

Interviews

Ethical AI Investment: The Key to Sustainable Healthcare Innovation...

In this exclusive interview, World Pharma Today sits down...

Interviews

Pharmaceutical Documentation Enters a New Era of Innovation

The future of pharmaceutical documentation is here - faster,...

Interviews

ChargePoint – Stretching Its Wingspan, Broadening Its Indian Footprint

When there’s too much that meets the eye, rest...

Interviews

Steriline’s Robotic Innovations in Pharmaceutical Manufacturing: A Conversation with...

World Pharma Today recently spoke with James Rorke, Vice...

Interviews

Interview with Dr. Manuela Schneider-Höfferer, Head of Commercial Development...

In Conversation with World Pharma Today at CPHI Milan...

White Papers

BioPharma

Press Releases

Drug Research

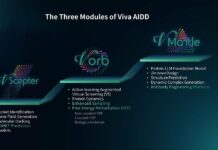

Viva Biotech Launches the AI-Driven Drug Discovery Platform, Transforming New Drug R&D Logic, Enabling One-Stop Innovative Drug Discovery

Artificial intelligence has rapidly evolved from academic theory into a transformative force in pharmaceutical R&D. From early QSAR models to neural networks, and now to AlphaFold3, AI...

Press Releases

Syntegon Reports Accelerated Growth in 2024 Results

Syntegon delivers record results in 2024

New strategy fuels accelerated growth following CEO transition in late 2023

Order intake increased by 11% to 1.8 billion EUR and...

Press Releases

Agilent Inaugurates India Solution Center to Accelerate Innovation and Expand the Frontiers of Science.

Integrated Facility to Deliver End-to-End, Customized Workflows Across Life Sciences, Diagnostics, and Applied Markets

India – Agilent today announced the opening of its first-ever India Solution Center at...

Press Releases

ACG Packaging Materials Earns SBTi Emission Target Nod

Mumbai, India, May 7, 2025 ACG Packaging Materials, a leading global supplier of integrated manufacturing solutions for the pharmaceutical and nutraceutical industries, has taken a significant step...

Press Releases

Kindeva bolsters executive team with Chief Quality Officer appointment

A global CDMO and drug delivery expert, has today announced the appointment of Melanie Cerullo as Chief Quality Officer to drive its quality, compliance and regulatory strategy....

Press Releases

Thermo Fisher Scientific Leverages Integrated Solutions to Accelerate the Development of Biologic Therapeutics

Thermo Fisher Scientific, a prominent figure in the scientific community, is utilising an advanced platform technology along with a new CHO K-1 cell line that can shorten...

Press Releases

Debiopharm and Oncodesign Services Launch Strategic Collaboration to Propel Radiopharmaceuticals in Preclinical Research

Martigny, Switzerland. Dijon, France – Debiopharm Research & Manufacturing S.A. (Debiopharm, www.debiopharm.com), a Swiss-based global biopharmaceutical company aiming to cure cancer and infectious diseases, and Oncodesign Services (www.oncodesign-services.com),...

Press Releases

Meribel Pharma Solutions launches with big ambitions to elevate pharma services to new heights

A new, mid-size Contract Development Manufacturing Organisation (CDMO), Meribel Pharma Solutions has launched today with an extensive integrated network across Europe, led by a team of industry experts...

Press Releases

Berry to Showcase Latest Technologies for Fast-to-Market, Patient-Centric Solutions

Solutions for patient-centred drug delivery devices that enhance dosing, administration, and medication adherence will be the focus of Berry Global Healthcare’s participation at this year’s RDD (Respiratory...

Subscribe

- Gain full access to our premium content

- Never miss a story with active notifications

- Browse free from any location or device.

Industry Reports

BioPharma

AI in Genomics Market – Setting Pace for Vast Genomic Data

There is no shred of doubt that artificial intelligence...

Industry Reports

Recyclable Pharma Packaging: Market To Hit $335B By 2032

There will be a lot more demand for recyclable...

Events

swop 2025 - Shanghai World of Packaging

-

Shanghai New International Expo Center (SNIEC), China

-

Nov 25 - Nov 27, 2025

BIO Asia-Taiwan 2025

-

Taipei Nangang Exhibition Center, Hall 1 & 2, Taipei, Taiwan

-

Jul 23 - Jul 27, 2025

Drug Devlopment

Asia’s CROs VCs: Blurring Service Provider & Investor Roles

In a time characterized by accelerated innovation and ever-more complicated clinical environments, Asia is witnessing an invigorating shift in...

Biopharma Production with AI: A New Era in Manufacturing

A New Era of Biopharma Production with AI

The biopharma industry is undergoing a transformation as it capitalises on the...

Packaging & Labelling

Recyclable Pharma Packaging: Market To Hit $335B By 2032

There will be a lot more demand for recyclable medicinal packages around the world. This means that the market...

Manufacturing

More News

Business & Industry

API China, PHARMCHINA & NHNE 2025 Conclude with Global Win

API China, PHARMCHINA & NHNE 2025 Close in Guangzhou with Thumping Success, Solidifying China as a World Pharma Leader

Guangzhou, May 24, 2025 — In a strong demonstration...

News

Under-Eye Wrinkle Treatment: How to Reduce Puffiness and Fine Lines

As we age, the skin around our eyes begins to show signs of wear and tear, with under-eye wrinkles, puffiness, and dark circles becoming common concerns. These...

News

Receptor Grade IGF-1 LR3: Expansive Research Potential

Receptor Grade IGF-1 LR3, an engineered analog of Insulin-like Growth Factor-1 (IGF-1), has emerged as a molecule of significant interest in scientific research. This peptide, studied for...

Business & Industry

API China 2025 kicks off with Industry Buzz on Day One

At the China Import and Export Fair Complex in Guangzhou, the 92nd edition of API China, the country's leading pharmaceutical trade fair, got off to a lively...

Technology

BioPharma

AI in Genomics Market – Setting Pace for Vast Genomic Data

There is no shred of doubt that artificial intelligence...

Industry Reports

Recyclable Pharma Packaging: Market To Hit $335B By 2032

There will be a lot more demand for recyclable...

Packaging & Labelling

Future of Drug Packaging: Safety, Sustainability, Innovation

The development of medication packaging stands out as a...

Videos

🔬 The Future of CROs in Rheumatology — Are You Ready?

00:43

Interview with Laurent Van Lerberghe and David Buller, Managing Partners, KELES

00:18

Happy International Women’s Day 2025

00:49

Merry Christmas & Happy New Year from World Pharma Today

00:29

Acing the Diverse Pharma Packaging Gamut

07:49

Digital Transformation: The Future of Pharma 🚀

00:47

J.POD Facilities - A Phenomenon in the making

03:35

Packaging Is Securing the Pharmaceutical Supply Chain

08:35

Cutting the regular CDMO perception with Adragos Pharma

04:12

CDMOs : Taking The Next-Gen Step Now

05:04